Managing Parts Categories Efficiently

If you’ve worked in dealership management, you know that managing inventory effectively is more than just knowing what’s in stock—it’s about ensuring every part has a purpose and that each category aligns with your operational goals. In this Insider’s Guide to Lightspeed blog, we’ll cover the essentials of changing parts categories, why it’s crucial, and how this feature can streamline operations and improve inventory accuracy.

Why Changing Parts Categories Matters

Keeping your inventory organized by accurate categories doesn’t just make your inventory reports cleaner—it directly impacts your business’s bottom line. By effectively categorizing parts, especially obsolete or slow-moving inventory, you make the ordering process more efficient and ensure that your accounting team has up-to-date information for financial tracking.

For example, having a category specifically for obsolete (OBS) parts allows you to mark items that are outdated or rarely sold. These parts can be set to bypass standard reorder methods, saving your team from unnecessary stock replenishment. Accounting departments will also benefit from this organization as they track items that may have different general ledger (GL) allocations or special inventory considerations.

Steps to Change Parts Categories in Lightspeed

Here’s how to get started:

- Set Up the Category

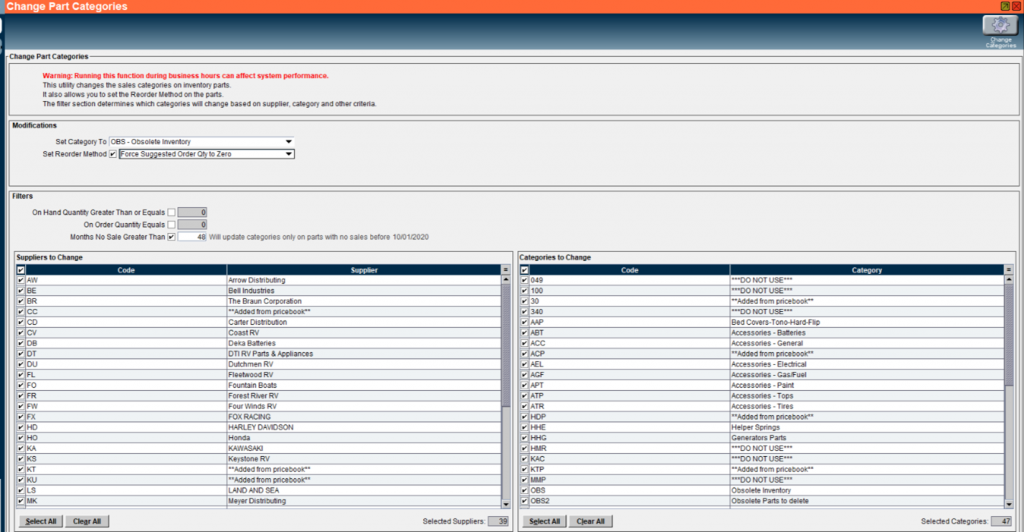

Begin by having your accounting team create a designated sales category for OBS (Obsolete) parts. This new category will act as a holding area for items that are no longer in demand or have been discontinued. Working with accounting ensures any adjustments align with GL accounts and financial records. - Access the Change Part Category Tool

Navigate to Parts – Inventory Updating – Change Part Category in Lightspeed. This tool is specifically designed to help dealers modify categories and organize parts by various criteria. - Add Filters

To effectively sort parts into the OBS category, use filters. You can filter by criteria such as:- Parts with no sales over the last few months or years

- Suppliers of the parts

- Existing categories to refine your search even further

This flexibility allows you to make targeted changes based on part performance, supplier, or how often the part sells.

- Select Reorder Methods

Once parts are in the OBS category, you can adjust reorder settings to manage their visibility and prevent unnecessary orders. Two critical methods to consider are:- Force Suggested Order Quantity to Zero

This method ensures parts in the OBS category won’t show up in your buying guide or on ordering screens, overriding regular sales calculations. This is useful for parts you’re phasing out or those with seasonal demand that you don’t want reordered automatically. - Force Desired Stocking Level to One

Ideal for parts you want to keep on hand but with limited stock, this method signals the buying guide to reorder just one item when quantities run out. It’s often used for items with unique demand patterns, like seasonal apparel or accessories.

- Force Suggested Order Quantity to Zero

- Finalize and Monitor

After making these changes, monitor how they affect your inventory flow, reorder patterns, and accounting. Regularly reviewing your parts categories and making adjustments keeps your dealership lean and responsive to shifts in demand.

Benefits of Properly Categorized Parts

- Reduced Overstock and Dead Stock

By marking obsolete parts correctly, you reduce the risk of over-ordering and carrying dead stock that ties up capital. Your inventory aligns with actual sales trends, so you’re only ordering what you need. - Streamlined Reordering Process

With reorder methods set strategically, your team can avoid wasting time on low-demand items and focus on high-demand products. This is especially useful during inventory seasons when accuracy and efficiency are top priorities. - Enhanced Financial Accuracy

Accurate categorization also improves your financial records. With parts properly assigned to the right GL accounts, you’re ensuring accounting has a clear picture of asset values, helping with budget planning and expense tracking. - Improved Buying Guide Efficiency

By adjusting reorder methods, you’re telling the buying guide exactly what you want it to focus on. The guide will show relevant items, simplifying decisions and allowing your parts team to focus on high-impact inventory.

Getting the Most from the Change Parts Categories Tool

Whether it’s handling seasonal inventory, phasing out discontinued parts, or setting up categories for accounting accuracy, the Change Parts Categories tool is invaluable. Used strategically, it can simplify your workflow, ensure inventory data is clean and accurate, and ultimately drive smarter business decisions. So make use of this feature today to optimize how you manage your inventory and keep your dealership running smoothly.